Glossary/Tolerances Perforated Metal

Perforations Perforations

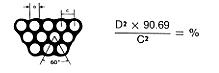

Round Perforations – Staggered (60 degree pattern) is standard.

Variations include 45 Degree Staggered, and Straight Line Pattern

Square Perforations – Staggered Pattern or Straight Line Pattern

Slotted Perforations – Side Staggered, End Staggered, or Straight

Lines. Slotted Perforations will be round end slots; specify if

square end slots are required.

Pattern of Perforations

Unfinished End Pattern – The condition which occurs with some

specifications of staggered pattern perforations as a result of

tool design. On one end of the plate, the pattern will appear to

be incomplete due to unperforated holes in the even numbered rows

while on the other end of the same plate, the pattern will appear

to be incomplete die to unperforated holes in the odd-numbered

rows.

Finished End Pattern – The condition which occurs with some

specifications of staggered pattern perforations as a result of

tool design, where the pattern is completed on both ends of the

plate.

Staggered Perforations, both round and square – Direction of the

stagger will normally be the short dimension of the sheet, as

illustrated in Fig. No.3 Straight row of holes is normally

parallel to long dimension of sheet.

Slotted Perforations – The long dimension of the slots can be

furnished parallel with either the width or length of the sheet in

most cases.

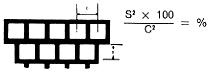

Formulas for Determining Percentage of Open Area

Staggered Round Holes

Square Holes (Straight or Staggered)

45 Degree Staggered Centers Pattern (Special)

Straight Round Holes

Square End Slot

Margins

Perforated Stock Size Sheets and Plates – The long sides of the

sheet will be supplied with minimum margins. The short sides of

the sheet will have either minimum margins or no margins

Sheets and Plates Resheared after Perforating – Special margins

are available to specifications but they must carry a tolerance

within the limits of the perforating tool. Unfinished end pattern

is standard in the industry. |

|

|